A packing error might seem small, but that’s all it takes to trigger chargebacks, delayed shipments, or an unhappy buyer who quietly walks away.

Read the article in Vietnamese here: Đâu là những lỗi đóng gói phổ biến và Làm thế nào để ngăn chặn chúng?

In the competitive world of retail manufacturing, the pressure to meet tight deadlines and buyer requirements is relentless. Yet, amidst this urgency, packing errors, seemingly small mistakes, continue to pose a major threat. They don’t just delay shipments or cause chargebacks; they quietly erode trust, one incorrect carton at a time.

What Is a Packing Error?

A packing error occurs when the items of a carton fail to comply with buyer requirements. These errors often go unnoticed until it’s too late, when the packing process is finished, or worse, when the shipment is already en route.

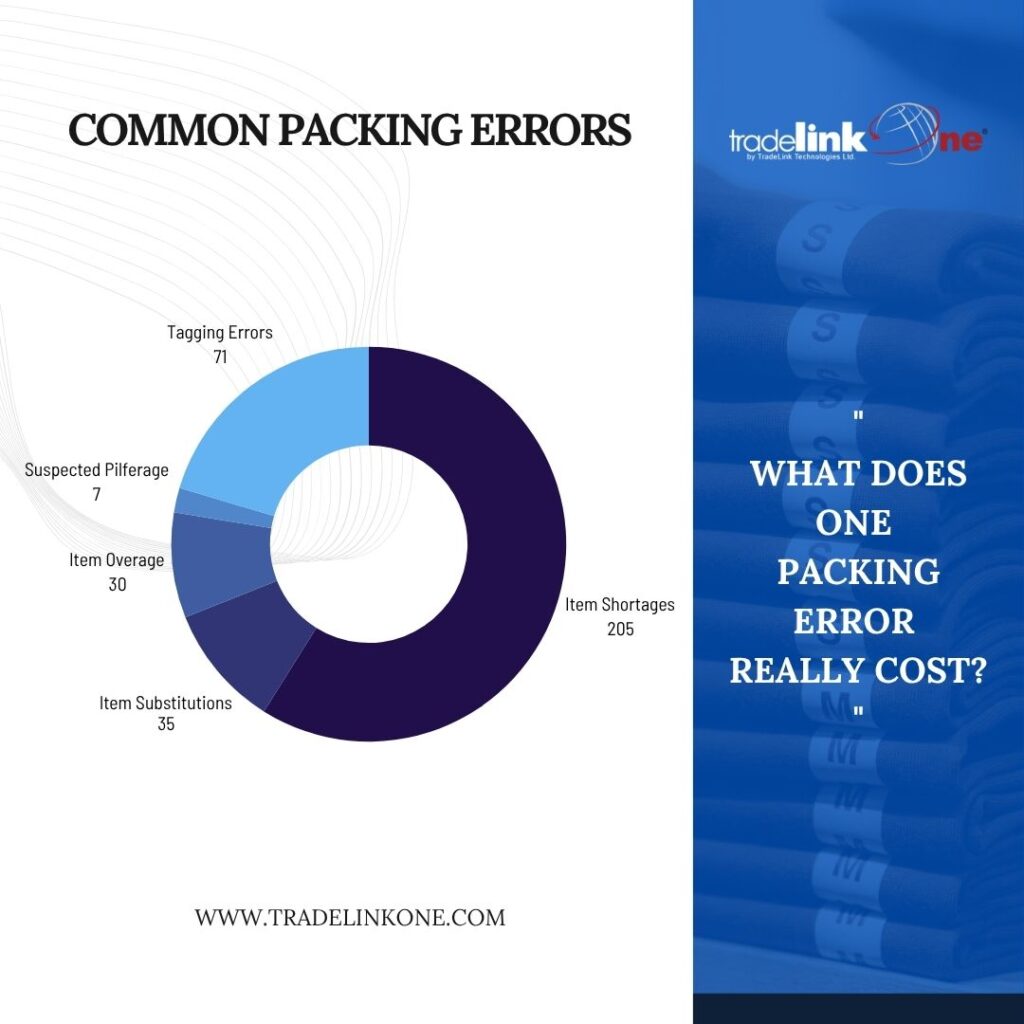

Typical examples include:

- Item Shortages – missing units compared to the order

- Item Substitutions – wrong style, color, or size

- Item Overages – extra units packed

- Suspected Pilferage – items stolen on the factory floor

- Tagging Errors – duplicate hangtags, missing, wrong, or malfunctioning RFID tags

What Does One Packing Error Cost?

- Late ShipmentsMost errors are detected only after packing is completed. Workers then have to locate, unpack, correct, and repack the cartons. Multiply that by dozens of errors, and your shipping schedule begins to unravel, causing delays and wasting valuable time and resources.

- ChargebacksMany buyers implement a chargeback policy for each incorrect carton. These penalties often range from $20 to $45 per box. It’s not just about the cost, it’s about the loss of margin on orders you’ve already worked hard to fulfill.

- Loss of TrustIn a competitive market, your reputation is everything. Repeated mistakes lead buyers to see your factory as unreliable. Even a single problematic shipment can put your next order in jeopardy.

- Operational Pressure During Peak SeasonDuring peak season, the stakes are even higher. Managers are racing against time, and adding more manual checks to ensure buyer compliance only increases stress and inefficiency. The solution isn’t more people, it’s smarter tools.

How to Prevent Packking Errors?

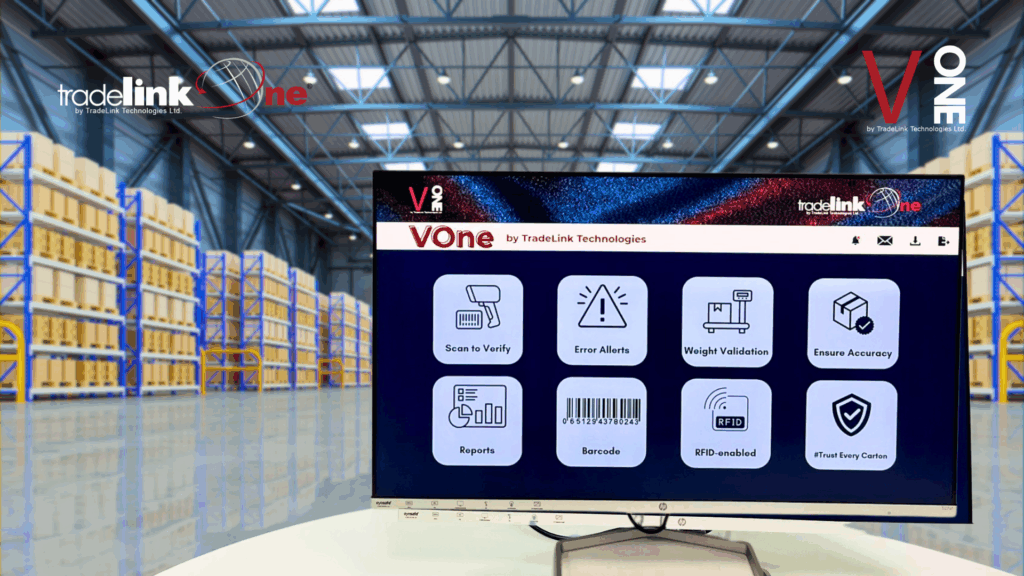

VOne, developed by TradeLink Technologies, is a lightweight, cost-effective solution that ensures compliance with buyer requirements while simplifying the validation process for packed cartons.

VOne: A Smarter Way to Prevent Packing Errors

- No EDI or PO connection needed. VOne works independently from buyer systems. This plug-and-play solution is ready for any factory, whether or not your buyer uses TradeLink.

- Fits your existing process. VOne leverages your Packing List and Pre-printed Carton Labels. If you already order labels from a printing partner, you can keep doing that, no process overhaul needed.

- How It Works: One Scan Away from Zero ChargebacksStep 1: Scan the Carton SSCC label.Step 2: Scan each item during packing. Step 3: Instant Validation. The system automatically detects packing errors (such as wrong, missing, or overpacked items) and checks compliance against the buyer’s rules.

- Transparent Data. Real-Time Reports.VOne provides auto-generated reports that help supervisors monitor packing activities in real time. Key reports include the Packing WIP Report, Scan-to-Verify Report, and Standard Container Load Status Report, all of which can be generated without limitations. These reports offer clear, transparent data to support decision-making and protect your factory from disputes or chargebacks.

- Fast Setup. Affordable Investment. Immediate Results.VOne is set up and running in just one day, with full local support from the local TradeLink team. It’s designed to be affordable, easy to use, and seamlessly integrated into your ongoing production, whether you’re already using printed labels or moving toward RFID.

VOne – A Strategic Choice for Your Factory

Technology doesn’t have to be complicated or expensive. VOne is designed with factories in mind, offering a solution that’s easy to deploy, requires minimal training, causes no disruption to your existing processes, and delivers tangible results from day one – all at a reasonable cost. If your goal is to eliminate packing errors, protect your margins, and build stronger relationships with buyers, VOne is the smart, practical choice for your factory.

Get a free demo today: support.vn@tradelinkone.com

—

About TradeLink Technologies,

TradeLink Technologies (TradeLink) was founded in 1999 with a mission to create advanced supply chain solutions for global brands and retailers. We provide visibility, accuracy, and advanced distribution solutions for over 400 global brands and more than 50 logistics companies, leveraging a network of over 12,000 suppliers across 70 countries. With our latest local and cloud-based scanning and barcode applications, our solutions are scalable to fit businesses of all sizes. TradeLink’s strength lies in our industry expertise in supply chain management and the utilization of cutting-edge technology. Learn more at: www.tradelinkone.com