RFID is steadily making its way into factories, quietly reshaping the way operations run.

This article follows up on: 3 Quiet Indicators That RFID Is No Longer a Distant Future.

Read the article in Vietnamese here: RFID Đang Đến Gần: Điều Này Có Ý Nghĩa Gì Với Nhà Máy Của Bạn?

A few years after its arrival, RFID has driven a shift toward efficiency and sustainability. While well established in retail across the United States, Europe and Asia, global brands are now pushing the technology upstream into manufacturing, reaching factories in China, India, Vietnam and other sourcing countries.

The essence of RFID lies in its ability to address current supply chain challenges. It can deliver notable improvements in operations, from accurate packing to efficient shipping.

The power of RFID lies in its ability to solve current challenges in today’s supply chains. It enhances accuracy and efficiency, while also paving the way for end-to-end traceability.

1. RFID: From Retail to Manufacturing

RFID has long been associated with retail, powering inventory management, loss prevention, and accelerate checkout processes. But its reach is no longer confined to the storefront. Step by step, RFID is moving upstream into the supply chain, , especially at its origin in the factories.

This shift is not just a passing trend. It reflects growing expectations for speed, accuracy, and transparency across global supply chains. With RFID, factories can track products from production through packing and shipment. Every item is ensured to reach the right place, on time, and in full compliance with vendor requirements.

For retailers, RFID has already delivered measurable savings in labor and operating costs. The same is now happening inside factories. Manual processes such as counting, packing, quality control, and container loading require large numbers of workers and still leave room for human error. Factories with RFID can run these processes with only a few staff members in each area, making operations faster, leaner, and more accurate.

2. Lower Costs and Wider Adoption

The truth is, one of the barriers to RFID adoption was that not every price tag carried an embedded RFID chip.

But that is no longer the case.

Falling RFID tag prices have accelerated adoption worldwide, with labels now costing as little as 0.05 to 1.50 US dollars each. As costs decline, brands are attaching RFID tags to more products, making them increasingly common on factory floors. At the same time, software, readers and infrastructure have become more flexible and affordable, enabling even small and medium manufacturers to benefit from greater efficiency, speed and transparency.

TradeLink’s RFID Pack & Scan Solution

3. What Can Factories Expect From RFID?

The strength of RFID lies in its simplicity and effectiveness.

- Accuracy: From packing to storage, shipping, and delivery, RFID ensures the right product is placed in the right carton, in the right quantity, and loaded onto the right container. It reduces errors, losses, and costly chargebacks.

- Faster Processes: Instead of scanning barcodes one by one, RFID can read multiple items at once. This accelerates packing, warehouse counts, and shipment preparation, while reducing labor time.

- Real-Time Tracking: Every step is monitored in real time, creating operational transparency. With accurate and timely data, managers are better equipped to plan ahead and make informed decisions.

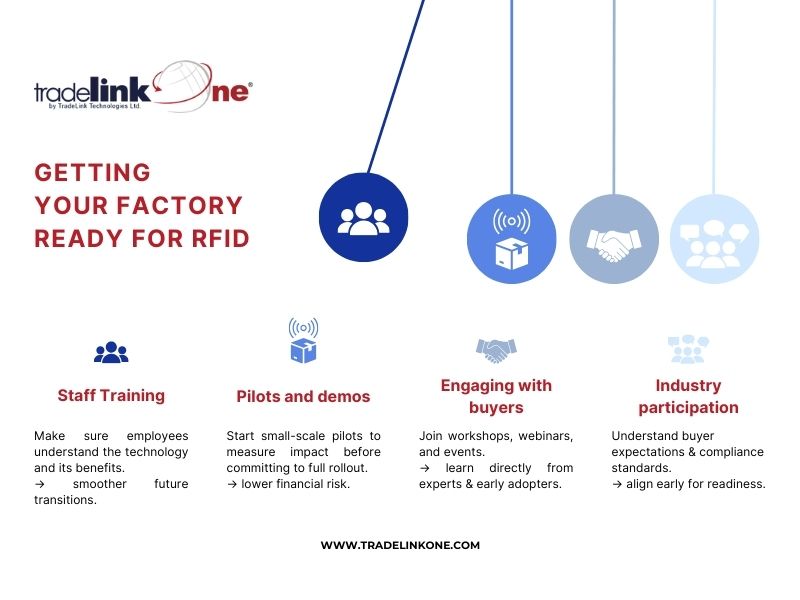

4. How Should Your Factory Prepare for RFID?

RFID is a promising investment, but preparation is essential before moving forward. Factories can begin with a few practical steps.

- Staff Training: Staff should be familiar with both the technology and its benefits. This foundation will make future transitions easier and faster.

- Pilots and demos: Rather than a full rollout, factories can start with small-scale pilots to measure RFID’s impact on existing processes without major financial risk.

- Engaging with buyers: Understanding customer expectations is critical. Do they already use RFID? Are there compliance standards you will need to meet? Aligning with buyers early ensures readiness.

- Industry participation: Workshops, webinars, and events are valuable opportunities to ask questions and learn directly from experts and factories already using RFID.

The Future of RFID: Advantage Belongs to the Prepared

For Vietnamese suppliers, RFID opens the door to a new play field, where efficiency, accuracy, and speed define success. Preparing now ensures that factories are ready when RFID becomes the standard. The best time to adapt is not when the entire industry has already moved, but before that moment arrives. Acting early means not only keeping up with the market but also taking the lead.

—

About TradeLink Technologies,

TradeLink Technologies (TradeLink) was founded in 1999 with a mission to create advanced supply chain solutions for global brands and retailers. We provide visibility, accuracy, and advanced distribution solutions for over 400 global brands and more than 50 logistics companies, leveraging a network of over 12,000 suppliers across 70 countries. With our latest local and cloud-based scanning and barcode applications, our solutions are scalable to fit businesses of all sizes. TradeLink’s strength lies in our industry expertise in supply chain management and the utilization of cutting-edge technology. Learn more at: www.tradelinkone.com